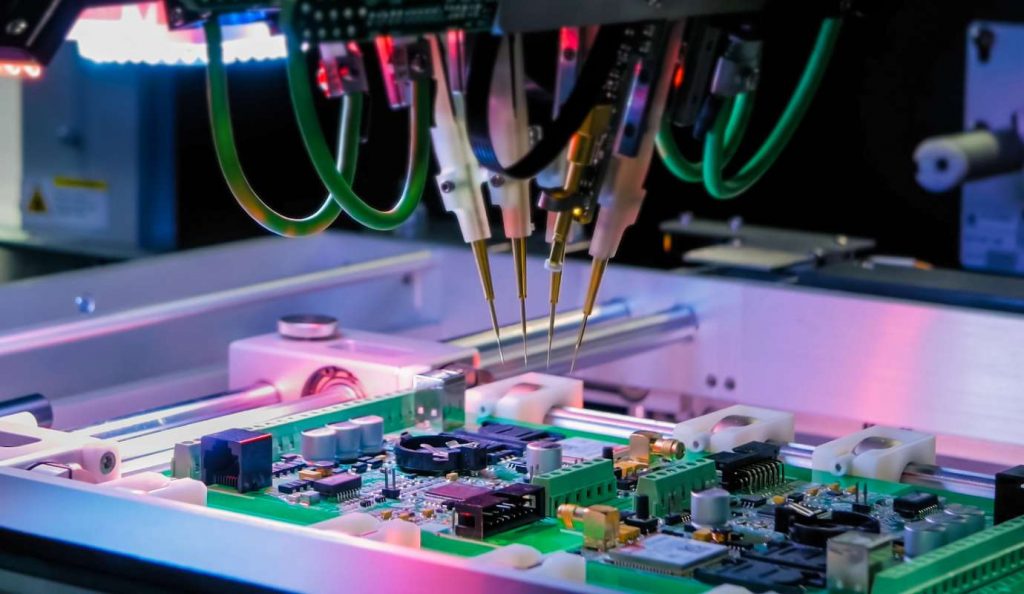

Double-sided circuit boards may be referred to as double-sided printed circuit boards or double-sided PCBs. They feature high wiring density, light weight, thin thickness, and good flexibility. They are an important part of the electrical connection of electronic components. The main advantage of double-sided circuit boards is that wiring and assembly errors are greatly reduced, and the level of automation and production labor is increased. What should we pay attention to when soldering double-sided pcb? Next, FS Tech will explain this knowledge to you.

Precautions for soldering double-sided pcb

1. After getting the bare PCB board, FS Technology will first visually inspect whether there is a short circuit, open circuit, etc., then familiarize yourself with the development board schematic, and compare the schematic with the silk screen layer of the PCB circuit board to avoid differences between the schematic and the PCB.

2. After the materials required for PCB soldering are ready, FSPCB will classify the components. All parts can be divided into categories by their size to facilitate subsequent welding. A full bill of materials needs to be printed. During the welding process, if there are items that are not welded, you can use a pen to cross out the corresponding options to facilitate subsequent welding operations.

Anti-static measures should be taken before welding, such as wearing an electrostatic ring to avoid damage to components caused by static electricity. After the equipment required for soldering is ready, the tip of the soldering iron should be kept clean and tidy. A flat angle soldering iron is recommended for initial soldering. When soldering components such as 0603 type packages, the soldering iron can better contact the pads for easy soldering. Of course, for experts, this is not a problem.

3. When selecting the components to be soldered, solder them in the order from low to high and from small to large. In order to avoid the inconvenience of welding larger components to welding smaller components. FS Tech recommends soldering IC chips first.

4. Before soldering an integrated circuit chip, it must be ensured that the chip is placed in the correct orientation. For the chip silk screen layer, generally the rectangular pad represents the starting pin. When soldering, one pin of the chip should be fixed first, the position of the components should be fine-tuned, and then the diagonal pins of the chip should be fixed, so that the components are accurately connected before soldering.

The learning of pcb knowledge is endless. If you want to learn related content, you can come to FS Technology PCB blog to learn about it, and we will publish the most authoritative pcb knowledge.